Rigid Enclosure

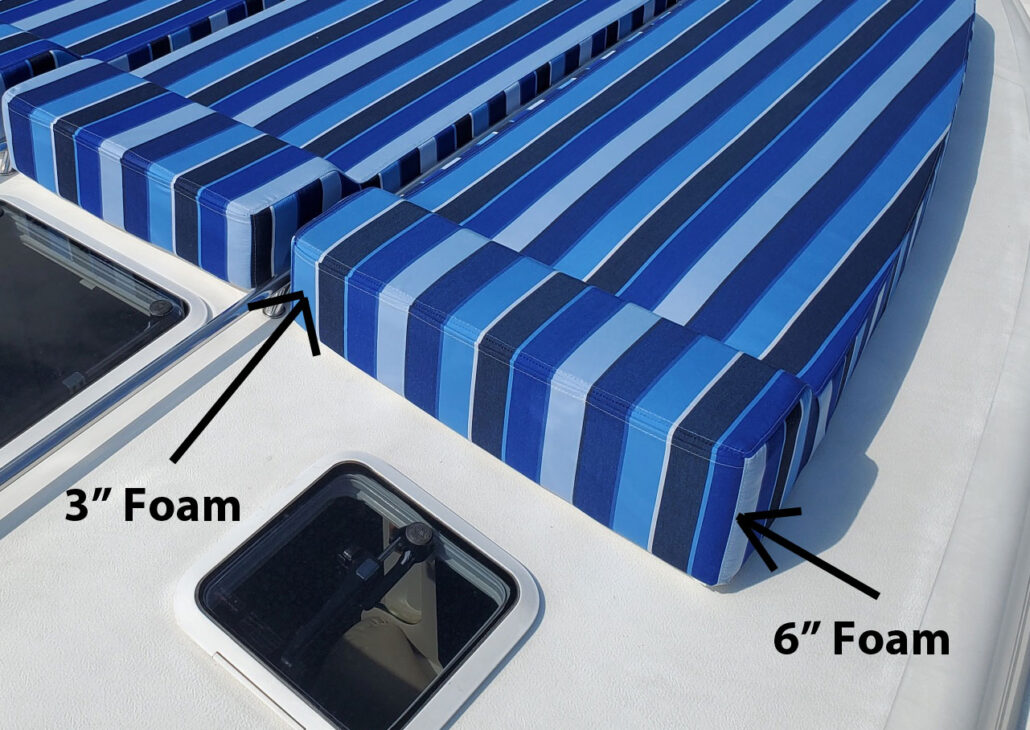

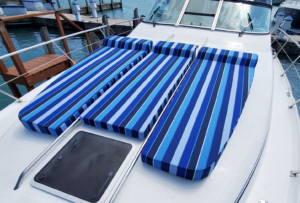

Custom Sun Pads

Custom Embroidery

Custom Sunpads / Bow Pads Features

Azimut 39′ Flybridge

A great way to update your boat is to update the flooring. This summer, while working with Crowley’s Yacht Yard, we got a job working on a Azimut 39′ Flybridge that involved all new interior and exterior flooring. As well as a new folding seat on the bridge. Crowley’s allows us year round access to all their customers boats in storage, allowing us to do work even when snow is around! This way your boat is ready to go when boating season is back!

A great way to update your boat is to update the flooring. This summer, while working with Crowley’s Yacht Yard, we got a job working on a Azimut 39′ Flybridge that involved all new interior and exterior flooring. As well as a new folding seat on the bridge. Crowley’s allows us year round access to all their customers boats in storage, allowing us to do work even when snow is around! This way your boat is ready to go when boating season is back!

For the exterior aft area, swim platform and interior bathrooms, we  used Dockside Decking in cream over black. This flooring was chose for this area of the boat because it is non-slip, shock absorbent, and reduces deck temperatures. It is also easy to clean and is stain resistant. Dockside decking is put on your boat, with an adhesive 3M backing, so its there to stay!

used Dockside Decking in cream over black. This flooring was chose for this area of the boat because it is non-slip, shock absorbent, and reduces deck temperatures. It is also easy to clean and is stain resistant. Dockside decking is put on your boat, with an adhesive 3M backing, so its there to stay!

Up on the flybridge we did some upholstery work. These customers wanted more seating on the flybridge when using the boat. They needed a seat that would fold down when the canvas was up on the boat. So we made a custom folding seat, that could be folded down when not in use. For the frame of this seat we used stainless steel tubing and hinges. For the base

Up on the flybridge we did some upholstery work. These customers wanted more seating on the flybridge when using the boat. They needed a seat that would fold down when the canvas was up on the boat. So we made a custom folding seat, that could be folded down when not in use. For the frame of this seat we used stainless steel tubing and hinges. For the base  of the seat and the backrest, we used starboard. Starboard is a marine grade plastic that we love to use on new upholstery work. It is non absorbent, which means that it won’t get water logged when it rains so it wont rot like wood. We did a full back upholstered bench seat with Ship 2 Shore vinyl. We did double needle stitching, to make sure that the new custom seat matched the existing seats on the flybridge.

of the seat and the backrest, we used starboard. Starboard is a marine grade plastic that we love to use on new upholstery work. It is non absorbent, which means that it won’t get water logged when it rains so it wont rot like wood. We did a full back upholstered bench seat with Ship 2 Shore vinyl. We did double needle stitching, to make sure that the new custom seat matched the existing seats on the flybridge.

Sea Ray Sundancer 460 Hardtop

We created five custom forward semi-rigid windows for this Sea Ray 460 Hardtop this summer. These windows flip up and attach to the hard top with a fastener. It allows the windows to stay up, but for extreme airflow if needed while out on the water.

For this forward enclosure, we used Tuffak (Markolon) polycarbonate for the window materials. Polycarbonate is a semi-rigid material, that is more stiff then Strataglass. Tuffak does not shrink or stretch in the sun, it stays the same size. This ensures that your canvas will always fit as perfectly as it did on the first day of install.

For the fabric the customer chose Sunbrella for their new enclosure. This fabric has a 10 year warranty. It is fade resistant and lasts while exposed to harsh weather elements. Sunbrella helps provide good protection from the sun. You can enjoy long hours out on your boat. It is breathable and allows air to pass through it. Sunbrella fabrics are also mold and mildew resistant. If exposure to certain debris cause this to happen, it can easily be cleaned with a simple bleach solution, without the canvas loosing its color.

We used SolarFix thread for these windows. SolarFix is a PTFE (PolyTetraFlouroEthylene) thread because of what it is made out of it has a lifetime guarantee. It is UV resistant and resistant to chemicals too, so this means that this customer will never need any re-stitching repairs. For zippers we used Lenzip plastic molded zippers which also have a life time guarantee on them. Here at Chicago Marine Canvas, we suggest you allow us to use the highest quality materials, that way your new cover, stays new for a long time, and you never need to get repairs!

We used SolarFix thread for these windows. SolarFix is a PTFE (PolyTetraFlouroEthylene) thread because of what it is made out of it has a lifetime guarantee. It is UV resistant and resistant to chemicals too, so this means that this customer will never need any re-stitching repairs. For zippers we used Lenzip plastic molded zippers which also have a life time guarantee on them. Here at Chicago Marine Canvas, we suggest you allow us to use the highest quality materials, that way your new cover, stays new for a long time, and you never need to get repairs!

Outdoor Kitchen Cover

Winter is just around the corner, which means it’s time to get a custom outdoor kitchen cover created. Here at Chicago Marine Canvas, we do custom covers, for any outdoor area, to protect it from the elements during our seasonal changes.

Winter is just around the corner, which means it’s time to get a custom outdoor kitchen cover created. Here at Chicago Marine Canvas, we do custom covers, for any outdoor area, to protect it from the elements during our seasonal changes.

We partnered with EDG Patio & Shade to help protect one of their recent jobs here in the Chicago area. EDG Patio & Shade does custom commercial, or residential spaces for people looking to spend more time outside!

For this outdoor kitchen cover we used Seamark in Toast Tweed. Seamark fabric, is Sunbrella fabric with a marine grade vinyl coating on the inside, this helps make it extra waterproof ensuring that no water, gets through the weave of the fabric.

We used Lenzip zippers on this outdoor kitchen cover which have a lifetime guarantee. We added zippers, so that the cover can allow easy access to different parts of the kitchen area. This way the customer can use the kitchen still, while the cover is still on other parts not

Winter Sailboat Cover – Cal 25 Sagatuck, MI

The owner of this Cal 25 contacted us to have a winter sailboat cover made for their boat which was being moved to Sagatuck, MI. The winters on the great lakes can be cold and snow fall totals can be in excess of 12″ per event. Instead of draping canvas over the boom and the rest of the hull we fabricated a heavy galvanized steel frame that would sit over all of the rigging and then rest outside of the lifelines. This would ultimately keep the cover off the Cal 25 sailboat itself but also allowed over 6′ of headroom underneath the cover to perform any maintenance or prep work before next season began.

The frame itself acts as a skeleton on top of the boat with a spine and then ribs supporting the winter sailboat cover. For practical purposes of installing and removing, the spine is broken into multiple pieces and joined. Each rib is fitted to spine with a through joint tightened down via screws. The equally spread out weight of the frame assists in stabilizing itself making it an extremely solid support structure. With rubber tips at the bottom of each rib the hull is protected from scratching.

The cover is split into a large forward and aft section adjoining together with a doubled up zipper and velcro flap. With the mast remaining up, we made small collars for each line, nine collars in total. The aft has an oversized access door that fully zippers down allowing large items to be moved in and out with the cover in place.

The beauty of our designs is the ease and quickness that the frame and cover can be installed. The frame is marked as to which pieces goes where and can be reconstructed in 30 minutes. The cover is then unfolded with all of the zippers securing around the mainstay lines. The collars to take time to zipper up and tie off but the install of the canvas should take another 1 hour. The bottom of the cover has connectors for lines made of webbing and not grommets which can scratch up the hull. It may take another 30 minutes to completely tie down the cover to the sailboat’s cradle. The goals is to have an easy to install / removed winter cover that be installed by 1 person in an afternoon.

Private Jet Service Carpet Runner

This past winter, Chicago Executive Airport contacted us, asking if we could do a carpet runner for one of their private jets. The Embraer Legacy 500 is a 12 passenger luxury jet with a 6 foot high cabin, fully berthing seats, and low cabin noise to make sure your journey is enjoyable. These customers wanted a floor runner for when the jet is in the hanger.

This past winter, Chicago Executive Airport contacted us, asking if we could do a carpet runner for one of their private jets. The Embraer Legacy 500 is a 12 passenger luxury jet with a 6 foot high cabin, fully berthing seats, and low cabin noise to make sure your journey is enjoyable. These customers wanted a floor runner for when the jet is in the hanger.

The first step to our process is heading out to the airplane to take measurements. This is a quick and easy process for us because of our 3D measuring device. It helps us precisely take measurements of the interior flooring of your jet, to ensure every millimeter will be covered. After we gather all the  measurements we need, we head back to our shop and start our design process. Here we use CAD (Computer-Aided- Design) Software to prepare our pattern for our seamstress. Finally, once we finish up our design process, we send the pattern over to our plotter. Which consequently draws out each piece to the pattern quickly and perfectly as a result.

measurements we need, we head back to our shop and start our design process. Here we use CAD (Computer-Aided- Design) Software to prepare our pattern for our seamstress. Finally, once we finish up our design process, we send the pattern over to our plotter. Which consequently draws out each piece to the pattern quickly and perfectly as a result.

For this service carpet runner, we used Grand Reserva vinyl. This vinyl has a polyester microsuede backing, so it is soft yet durable on both the front,  and the back. Above all, this is an aircraft certified vinyl that is flame resistant, anti-microable, and anti-bacterial. Most noteworthy, you can clean this fabric with just a mild soap and water. We used Solarfix thread on this carpet runner. SolarFix has a lifetime guarantee. It is UV, chemical, and weather resistant.

and the back. Above all, this is an aircraft certified vinyl that is flame resistant, anti-microable, and anti-bacterial. Most noteworthy, you can clean this fabric with just a mild soap and water. We used Solarfix thread on this carpet runner. SolarFix has a lifetime guarantee. It is UV, chemical, and weather resistant.

Right now, we are currently in the process to begin to work on aircraft upholstery through the FAA! This is super exciting and allows us to open our doors to the aircraft world!